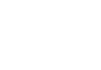

Tube cut

The wide variety of tubes used in shock absorber manufacture requires tube cutting machines to be flexible when it comes to the diameters to be processed, as well as a short...

More informationDeformation

Both in simple processes such as tube notching and in complex processes for obtaining tubes of variable thickness, LAUNIK is capable of designing and executing the entire...

More informationWelding

Welding, in its different application variants, is one of the most common joining processes in the industrial world and particularly in the automotive sector.

More informationPunching

The punching, both of the shock absorber clamp and of other holes in the tube, is done hydraulically or servomotorised depending on the customer's requirements and on whether...

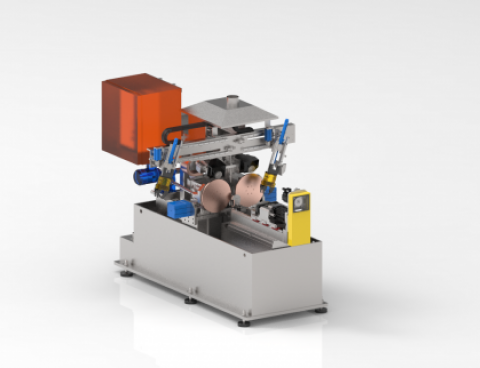

More informationRiveting

Based on its own technology, LAUNIk has servo-controlled riveting machines to carry out the riveting process with the highest quality and reliability.

More informationPressing

Using both commercially available equipment and its own presses, LAUNIK carries out all kinds of pressing operations on components with the highest reliability, mechanical load...

More informationFlanging

Applicable both in the shock absorber manufacturing process and in the mounting of ball joints on suspension links and other elements, the flanging process is one of the...

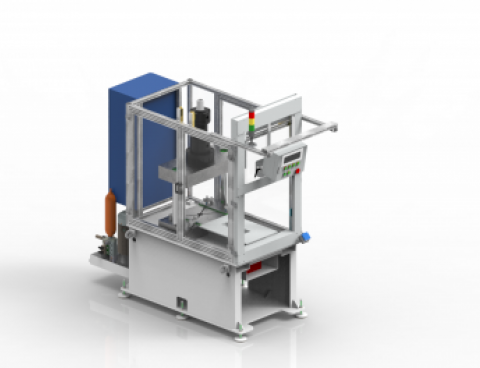

More informationTest

LAUNIK has extensive experience in testing and checking components such as shock absorbers, clutches, ball joints and hinges, implemented in independent workstations or...

More informationAssembly

Component assembly processes is one of the fields in which LAU-NIK has developed projects for the manufacture of shock absorbers, hinges and ball joints, among others, and in...

More informationVisión

Today, industrial vision systems are one of the applications most frequently used to control mechanical system assembly processes.

More informationMarking

Included within component and product traceability systems, marking is one of the systems most requested by our customers.

More informationGrease application

Every special component manufacturing and / or assembling machine needs to integrate greasing stations or other fluid application systems:

More informationServo presses

For applications in which force and position control are both critical, LAU-NIK uses servo controlled presses from the leading manufacturers on the market.

More informationFeeders

Used in many applications within special machinery, feeders are essential to achieving high speed and reliability in the component feeding process for the assembly of...

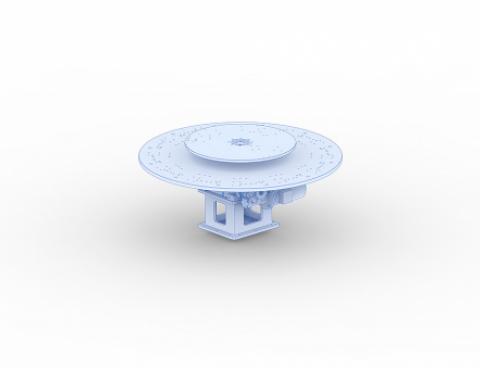

More informationDivider plates

In any assembly cell in which the integration of multiple assembly processes requires use of divider plates (or indexers), the precision and reliability of these components is...

More informationGrippers

In any high speed production cell, part manipulators are one of the components subject to the highest mechanical stress and must maintain their precision and mechanical...

More informationWelding

For the special machines developed for the manufacture of welded mechanical subassemblies, LAU-NIK uses the latest generation welding technologies:

More information