Sectors

Suspension

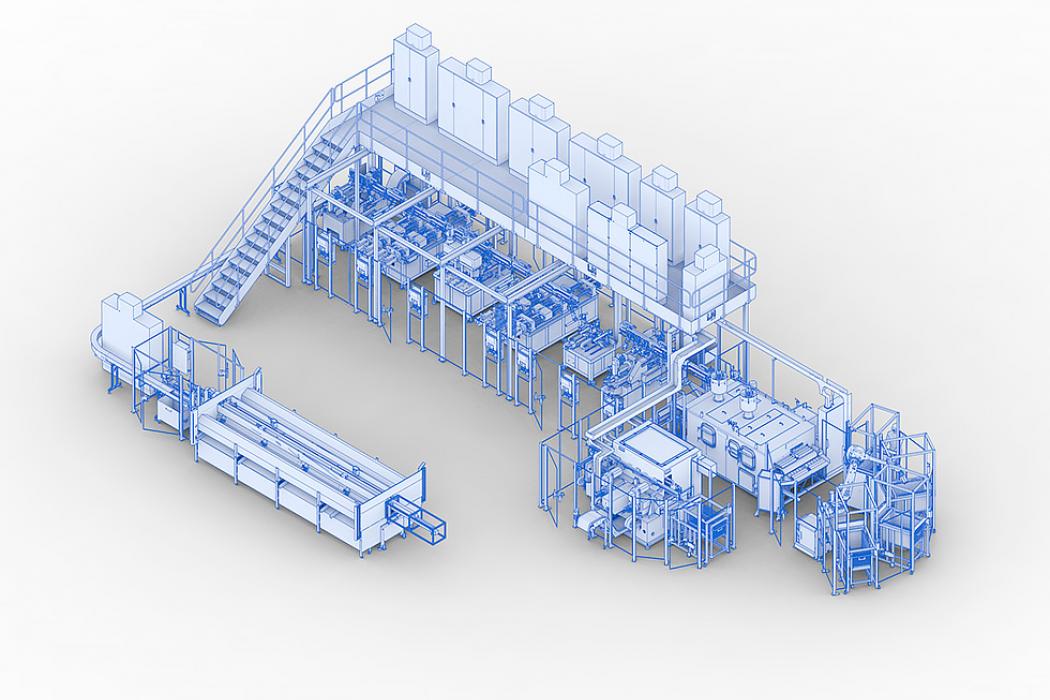

Tube manufacturing lines

LAUNIK provides the most complete shock absorber tube manufacturing lines for the simplest (mono-tube) and the most complex (electronic) shock absorbers.

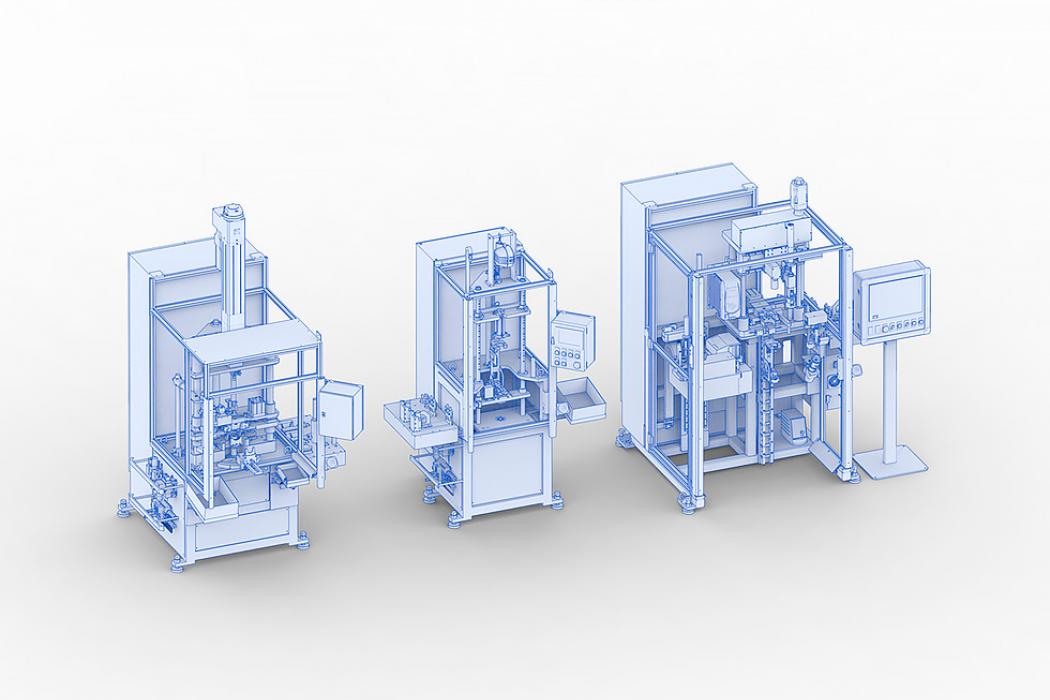

Tube forming machines (punching / pressing)

Both comprehensively on the assembly line and individually, LAUNIK carries out all the operations involved in the manufacture of the shock absorber tube, including the cutting, shrinking, chamfering and facing, punching, CNC machining, cap setting, welding (resistance or MAG) and marking (rolling, laser and micro-percussion)

Stem finishing lines

Once the stem chrome plating and grinding operations have been performed, LAUNIK provides automated solutions for the final finishing of the stem prior to its integration into the assembly process, such as drilling, threading, broaching, checking and marking.

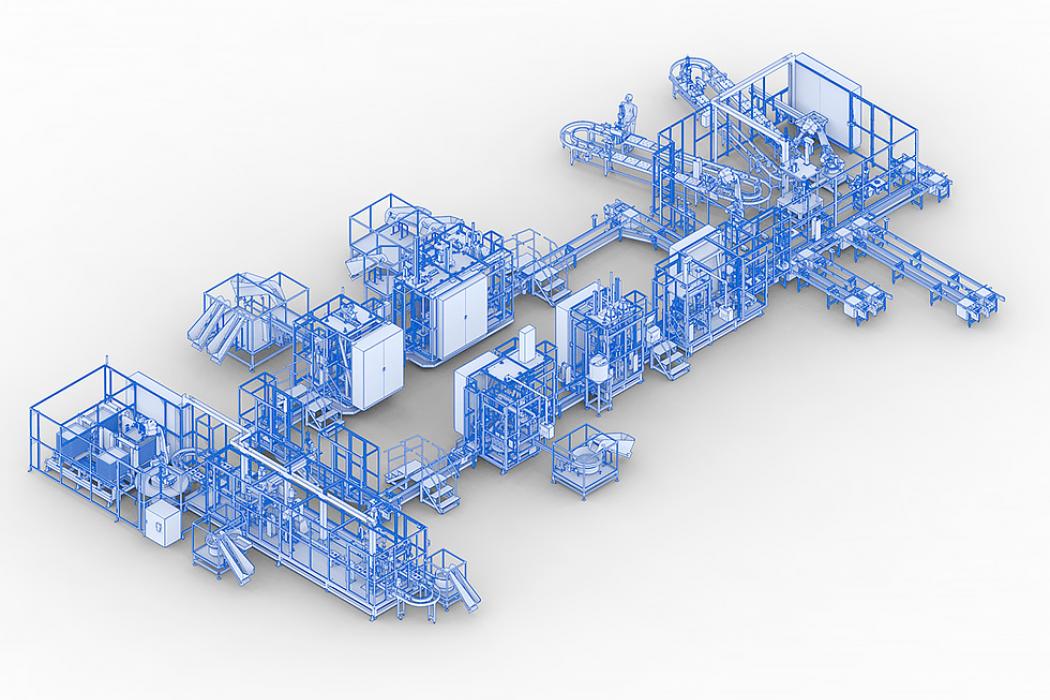

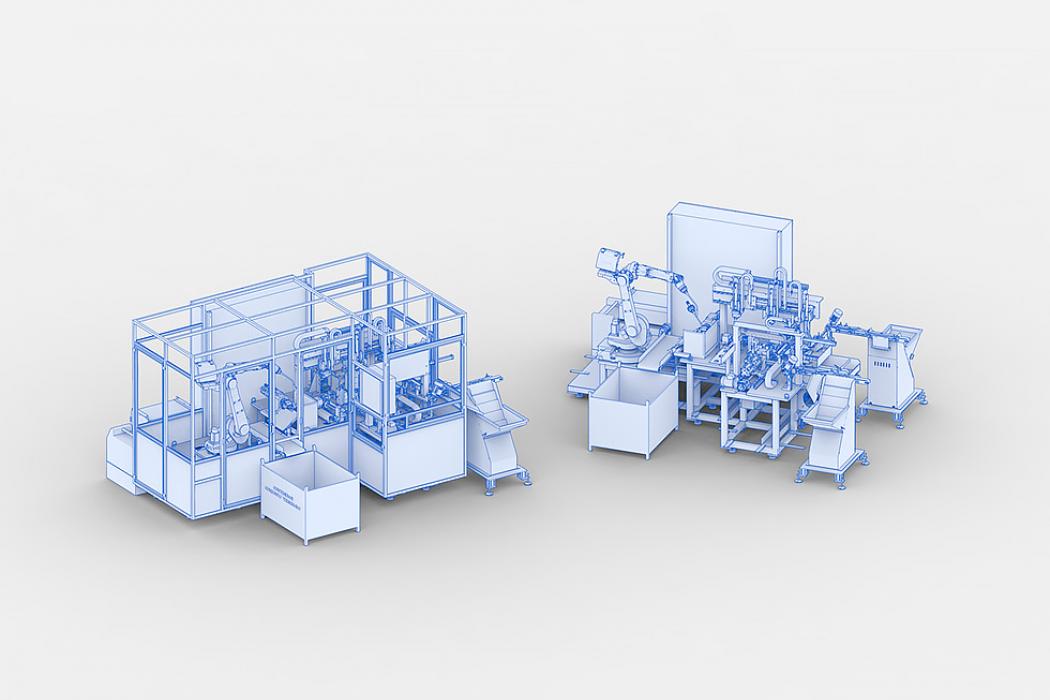

Shock absorber assembly lines

LAUNIK provides the most complete assembly lines for all shock absorber components, including the simplest (mono-tube) and the most complex (electronic) shock-absorbers.

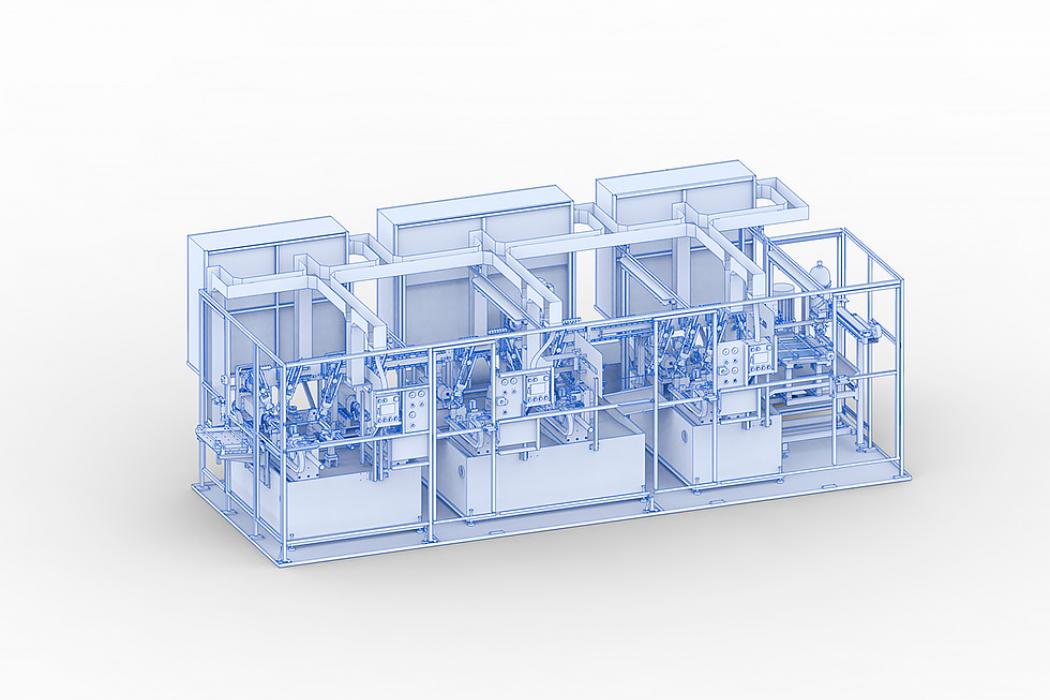

Modular shock absorber assembly machines

Both comprehensively on the assembly line and individually, LAUNIK carries out all the operations involved in the complete assembly of the shock absorber, using technologies like pressing, flanging, handling and feeding of components, measuring, vision and marking.

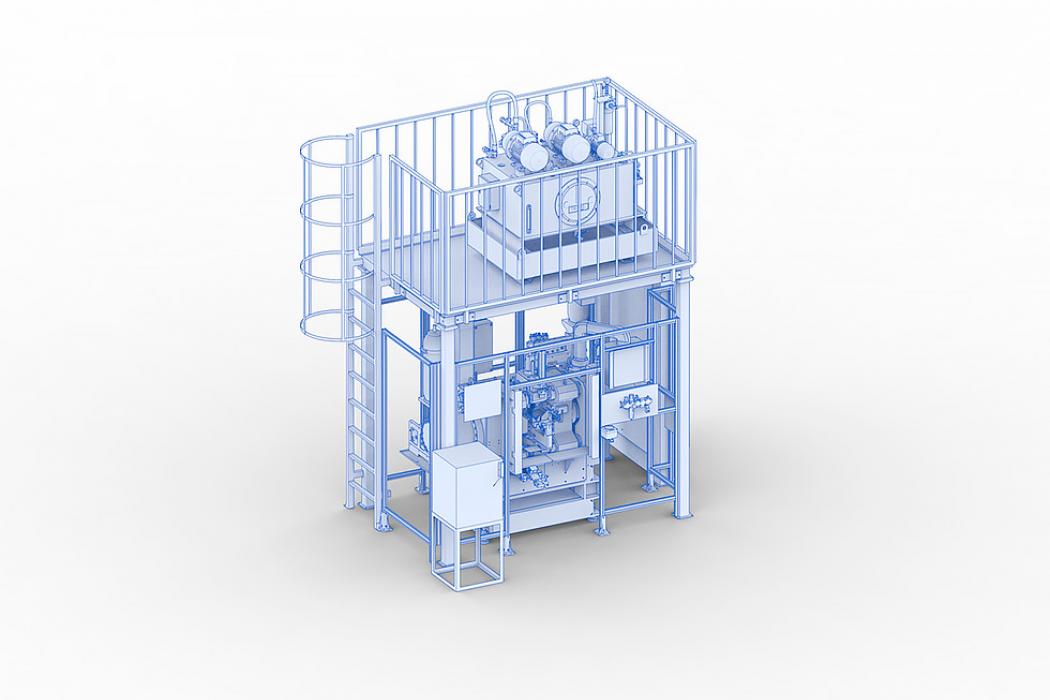

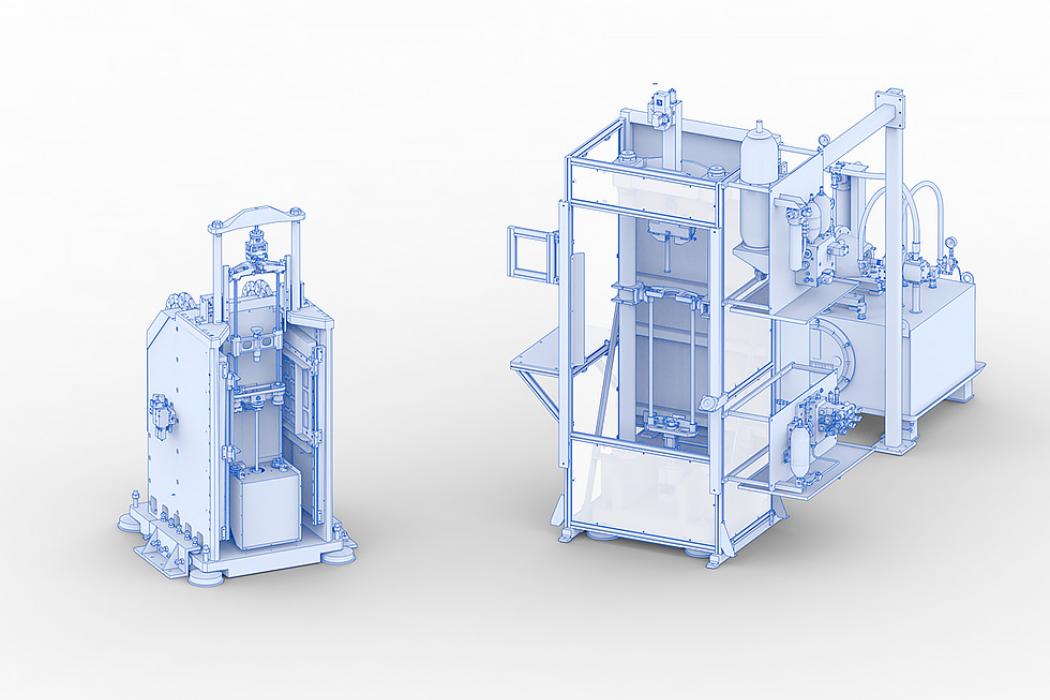

Shock absorber testing machines

Once the shock absorber has been assembled, LAUNIK carries out the gas loading and testing (hydraulic or linear-motor) operations with precision and reliability in order to ensure optimal operation within the highest quality standards.

Suspension link / arm welding cells

LAU-NIK is also a supplier of automated suspension link and arm welding cells, for both resistance and arc welding technologies.

Automotive industry

Automotive industry Foundry Casting

Foundry Casting Industry

Industry Renewables

Renewables